| ORDER NO | A | B | C | D | E | F | G | H | MAX. Clamp Force (kgf) | G.W. (kgs) | CODE NO. |

|---|---|---|---|---|---|---|---|---|---|---|---|

| ET 01 4 | 477 | 425 | 172 | 240 | 155 | 87 | 130 | 495 | 2500 | 36 | ET-6A |

Error: Contact form not found.

The general prototype development process for casting components in engineering applications involves several key steps:

Design Conceptualization: Engineers conceptualize the design of the casting component based on functional requirements, performance criteria, and material considerations.

CAD Modeling: Computer-aided design (CAD) software is used to create detailed 3D models of the component, including all dimensions, features, and specifications.

Material Selection: The appropriate casting material is chosen based on factors such as strength, durability, heat resistance, and cost-effectiveness.

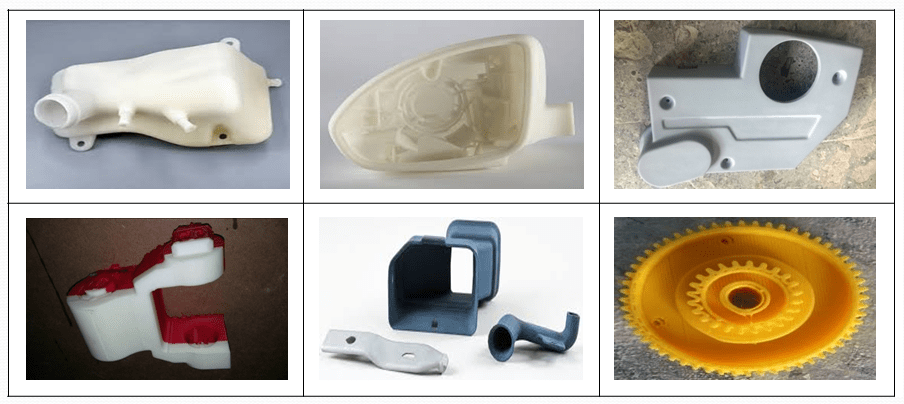

Prototype Fabrication: Prototypes are produced using various techniques such as 3D printing, CNC machining, or rapid prototyping. These prototypes are typically made from materials that closely mimic the properties of the final casting material.

Testing and Validation: Prototypes undergo rigorous testing to evaluate their performance, durability, and fitment. This may involve mechanical testing, stress analysis, and functional testing under simulated operating conditions.

Iterative Design Refinement: Based on the results of testing, the design may be refined and optimized to improve performance, address any issues, or meet specific requirements.

Tooling Design: Once the prototype design is finalized, tooling such as molds or patterns is designed to facilitate the casting process for batch production.

Batch Production: Batch production of the casting component begins using the finalized tooling and casting process. This involves melting the casting material, pouring it into the molds, and allowing it to solidify.

Finishing Operations: After casting, the components undergo finishing operations such as machining, grinding, and surface treatment to achieve the desired dimensions, surface finish, and tolerances.

Quality Control: Throughout the manufacturing process, stringent quality control measures are implemented to ensure that the casting components meet specified standards for dimensional accuracy, material properties, and performance characteristics.

By following this general prototype development process, engineers can design and manufacture casting components that meet the demanding requirements of engineering applications, ensuring reliability, performance, and functionality.

31-B , Sector-A , Industrial Area , Sanwer Road , Indore -452015 (M.P) India.

Tel : +91-731-2974869,

+91-98260-24869,

+91-98930-26489

New, Sector-A, Sanwer Road, Bajrang Pura,

Indore, Madhya Pradesh 452006

Mobile No . 09993971001

WhatsApp us