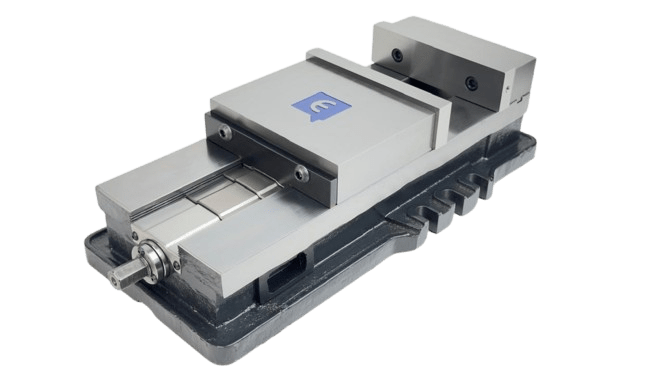

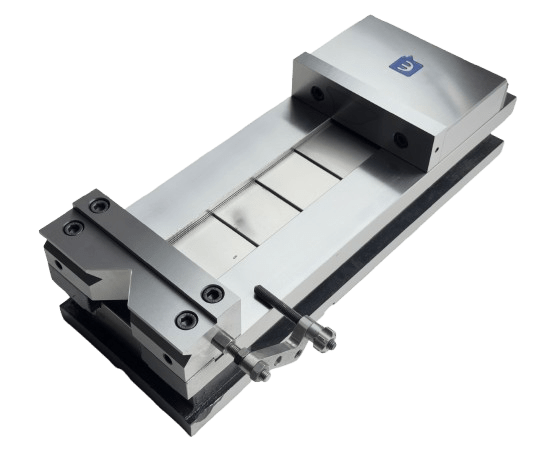

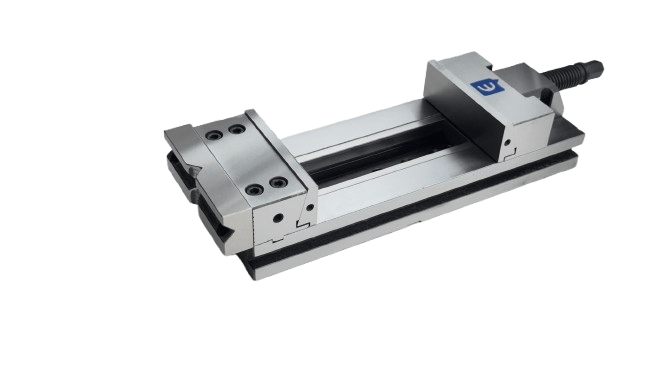

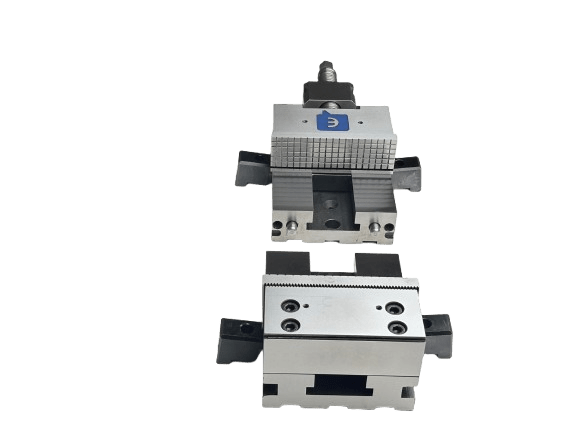

| ORDER NO | A | B | C | D | E | F | G | H | MAX. Clamp Force (kgf) | G.W. (kgs) | CODE NO. |

|---|---|---|---|---|---|---|---|---|---|---|---|

| ET 01 4 | 477 | 425 | 172 | 240 | 155 | 87 | 130 | 495 | 2500 | 36 | ET-6A |

Error: Contact form not found.

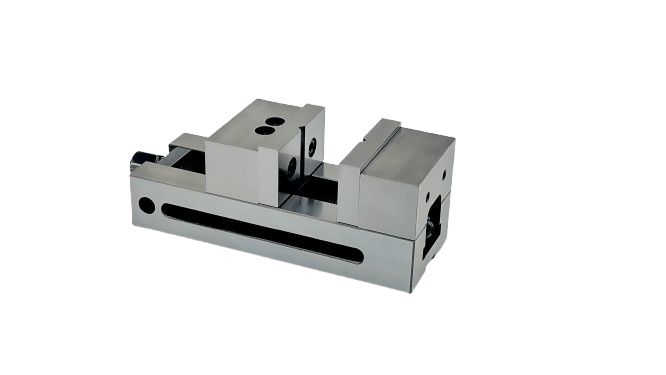

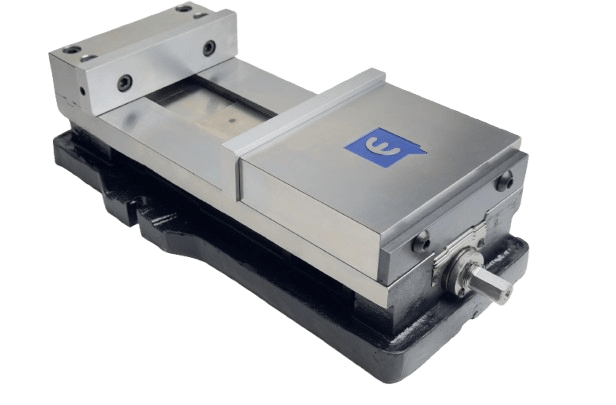

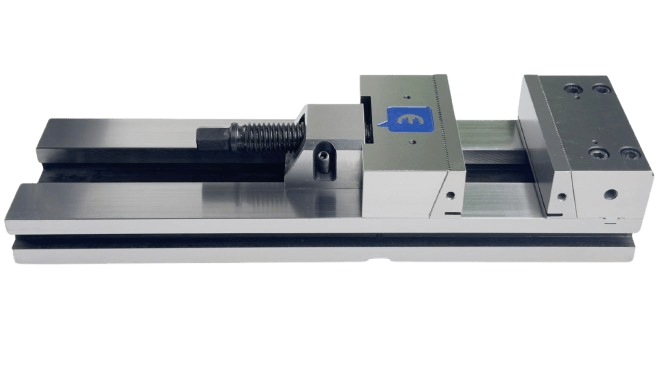

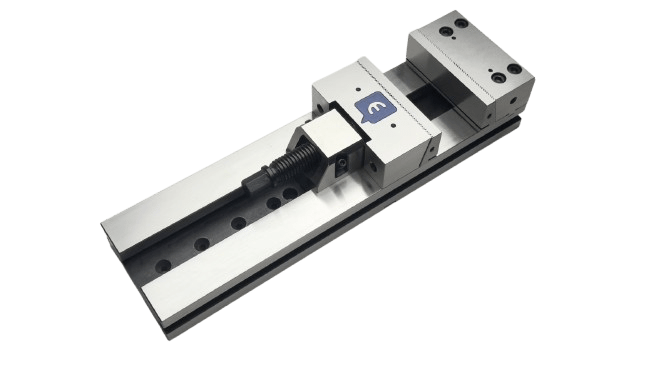

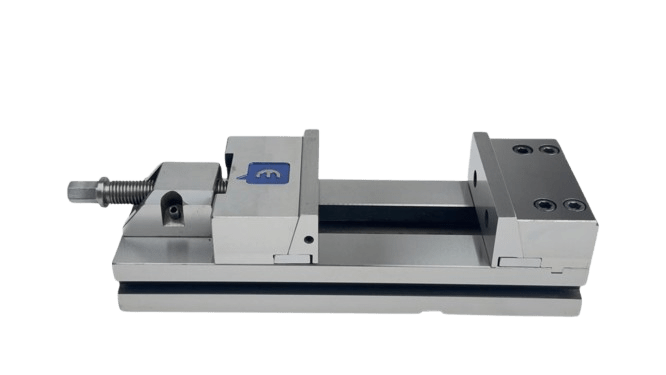

A Standard machine vise with a telescope cover made of SS 304 is a robust solution for protecting the lead screw and box nut from cutting chips, scrap, and coolant in machining operations. The vise body, crafted from ductile iron with a hardened bed, ensures durability and stability during clamping.

The telescope cover, constructed from corrosion-resistant SS 304 stainless steel, provides reliable protection for the lead screw and box nut mechanism, shielding them from debris and coolant splashes. This helps to maintain the integrity and smooth operation of the vise over time.

Available in various sizes to accommodate different workpiece dimensions, these vises offer versatility and precision in machining setups. Features such as precision-ground jaws, quick-release mechanisms, bases enhance functionality and ease of use.

Overall, a compact machine vise with SS 304 telescope cover, combined with ductile iron construction and a hardened bed, provides durability, reliability, and protection in machining environments, ensuring efficient and precise clamping while safeguarding critical components from damage.

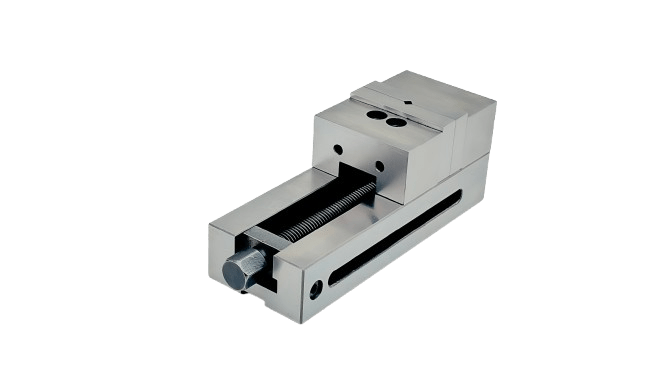

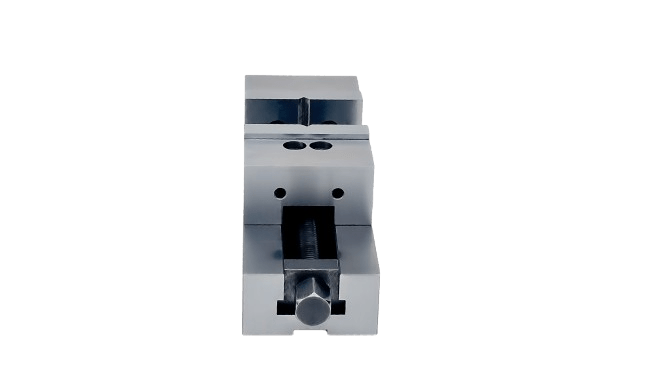

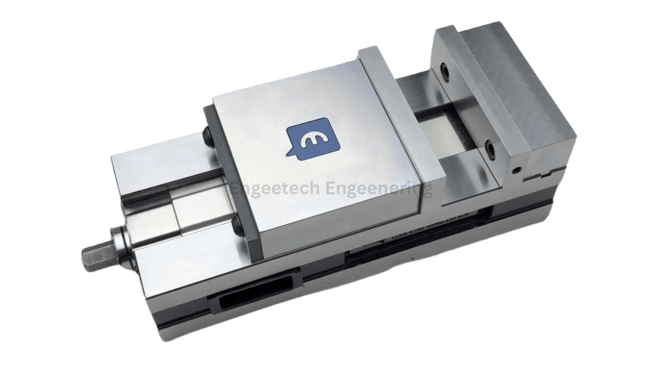

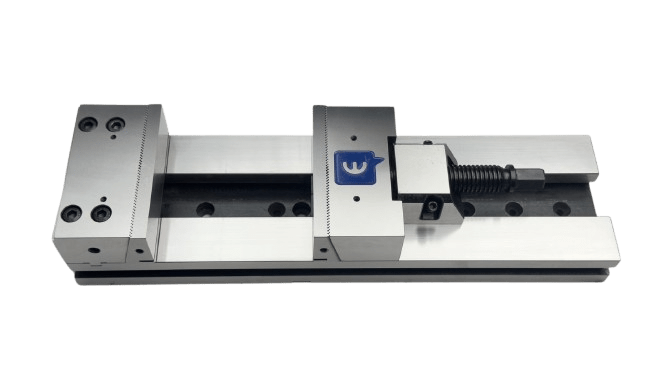

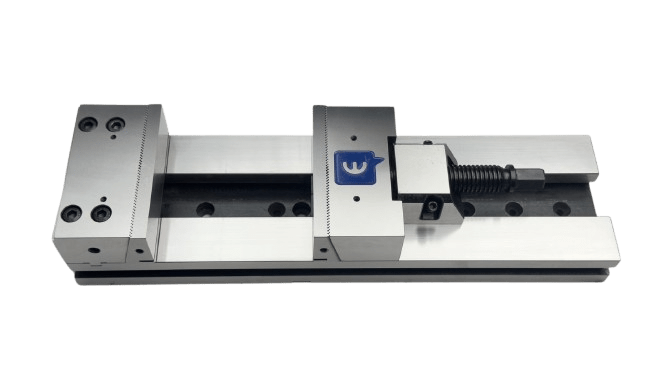

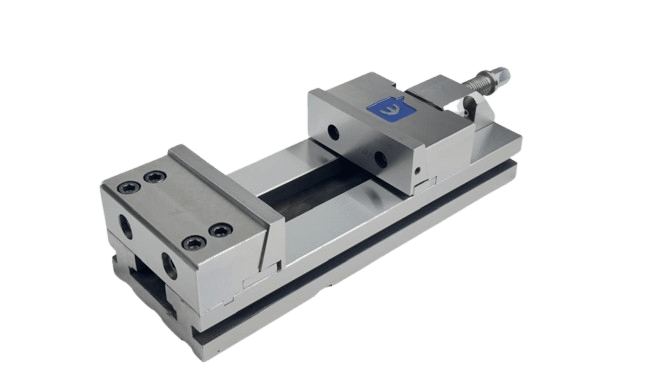

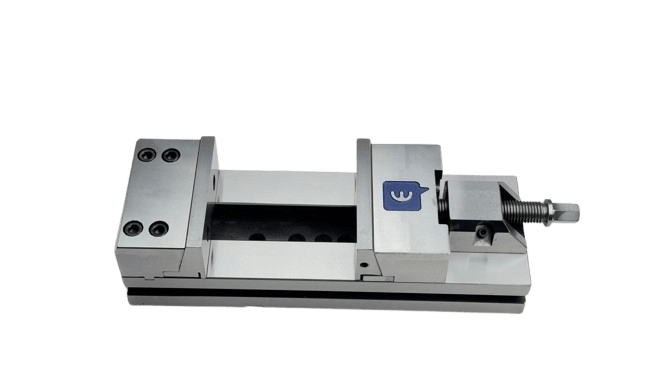

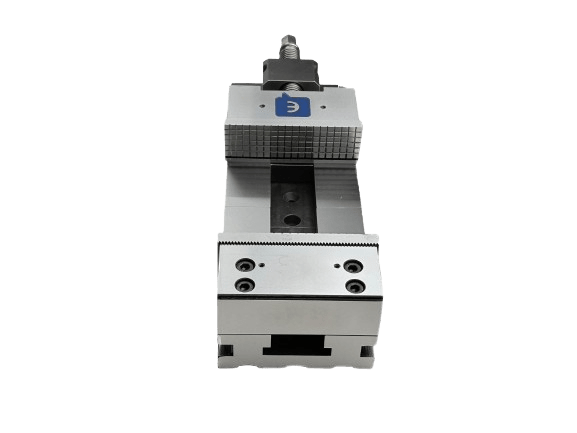

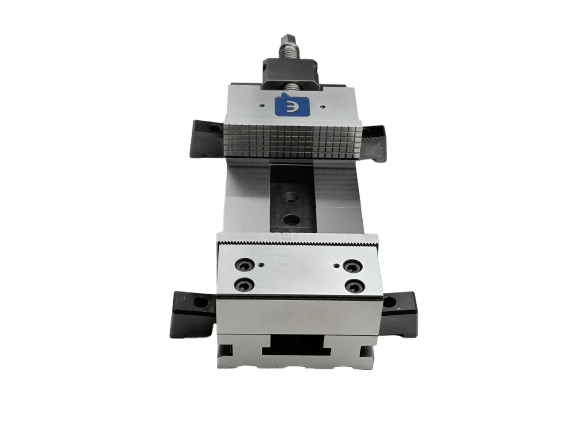

A COMPACT machine vise equipped with a telescope cover made of SS 304 stainless steel provides robust protection for the lead screw and box nut, preventing damage from cutting chips, scrap, and coolant. Crafted from ductile iron with a hardened bed, these vises ensure stability and durability during machining operations.

Available in various sizes to accommodate different workpiece dimensions, these vises offer versatility and precision. The telescope cover, constructed from corrosion-resistant SS 304 stainless steel, shields the lead screw and box nut mechanism, maintaining their integrity and smooth operation.

Features such as precision-ground jaws, quick-release mechanisms, and swivel bases enhance functionality and ease of use. Overall, a standard machine vise with an SS 304 telescope cover, paired with ductile iron construction and a hardened bed, delivers durability, reliability, and protection in machining environments, ensuring efficient and precise clamping while safeguarding critical components from damage.

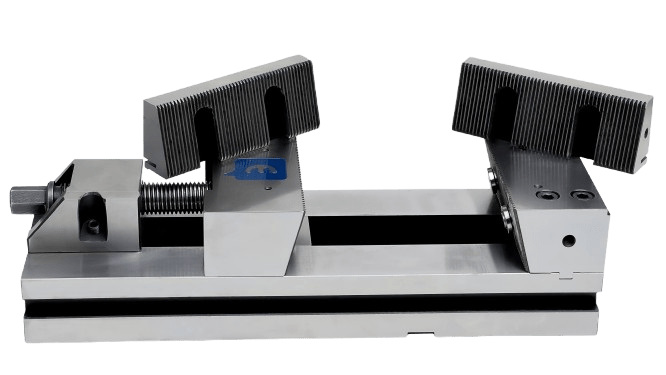

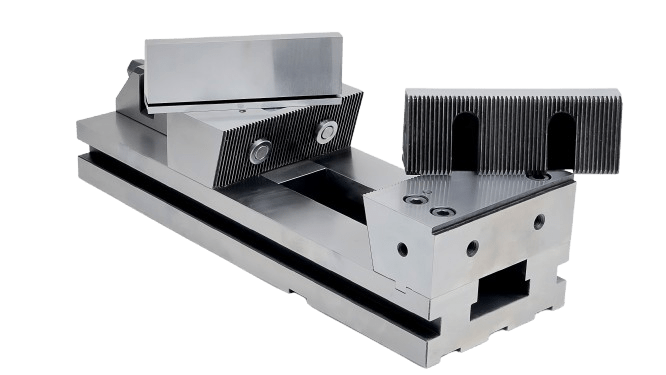

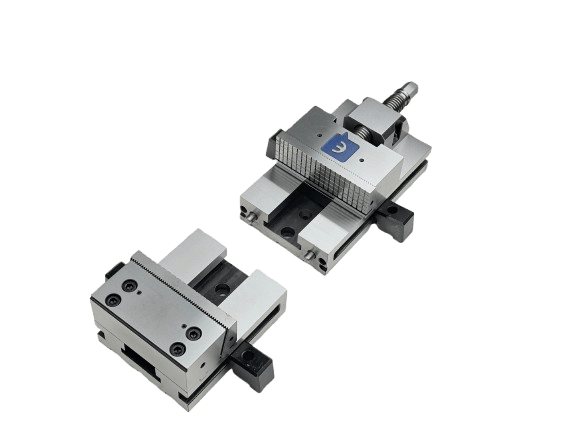

With Serration Jaw

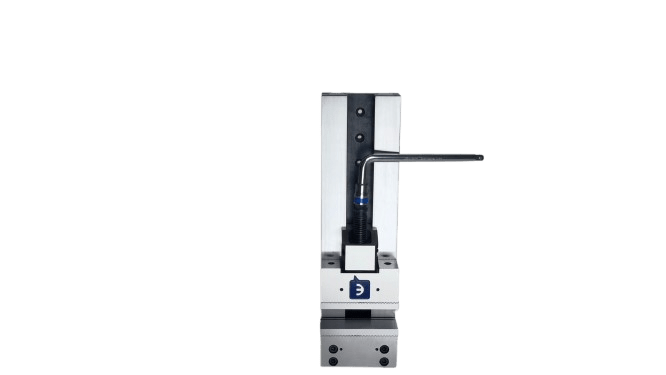

Large Surface Machining with Distributed Clamping

Rapid Prototyping and One-Off Production

Custom Fixturing and Advanced Fixture Design

31-B , Sector-A , Industrial Area , Sanwer Road , Indore -452015 (M.P) India.

Tel : +91-731-2974869,

+91-98260-24869,

+91-98930-26489

New, Sector-A, Sanwer Road, Bajrang Pura,

Indore, Madhya Pradesh 452006

Mobile No . 09993971001

WhatsApp us